GOODWIN MILL AND CABINETS was recently asked on Facebook how much it would cost to change the color of a set of cabinets. First off, let me say I think this is a super smart decision on your part. Improving cabinetry is one of the best ways to improve the value of your home. And now I'd like to explain why that's not a simple question and why I can't guess at a price.

When it comes to changing the color of cabinets one of the first things you have to do is determine what type of exposed material you have on your cabinets. Are your doors and drawer fronts made of wood or a composite material?

Wood doors and drawer fronts are most common with stain finishes. These types of finishes accentuate the wood grain and use it to create character in the final product. If you can see the gain in the wood, chances are, it's a solid wood door or front.

Changing the color on a wood door or front can be a time consuming and expensive process. Mainly because of the work it takes to strip the existing finish away and sand the material down to where you can add a new color without the old color showing through. When a cabinet is finished, the final coat is a protective layer used to help protect the wood from warping if it gets wet and to maintain its appearance. This finish coat is what will initially be the hard substance to strip away. It requires the use of some potent chemicals that need to be applied directly on the door or front to break down the coating. Then the material must be wiped or sanded as leaving the thinner/stripper on the wood will cause it to warp. Depending on the wood and finish type, multiple applications may be required to remove the stain and protective topcoat.

Once you've done that, you have to sand the material to remove traces of the previous color and prepare the wood to take on a new color. This process can also take a fair amount of time as depending on how ornate the door or front, smaller edges and details will have to be sanded by hand.

There are two types of composite material you could also run into. Most painted cabinetry will use composite material for the doors and fronts as they allow the paint to sit flatly and have a better sheen. There's no wood grain detail usually, but it will have a protective coat.

It's usually cheaper than wood and is popular because it has so many more color options and can be coordinated with other color choices in the home. Plus, the color is consistent across the surface of your cabinetry. If you have doors and drawers of this type, you have to sand them in order to scuff them up before you can cover them with a new coat of paint.

The second type of composite material is similar to melamine. It comes with a veneer surface. This material is covered on all sides with a plastic veneer often mimicking the appearance of wood that can be textured or flat depending on your aesthetic choice.

Changing the color on this type of product is pointless. You would simply remove the doors and fronts and proceed to my final option as this material is simply produced in the color originally chosen for the job. It comes in large sheets we cut down to individual size. The front and back are already covered with the veneer so the only thing we do to finish the door or front is band the edges with the same color veneer material.

The other option is to scrap the doors and drawer fronts and make new ones to replace them. In the case of the veneer composite material, this would be the option. With the paint grade composite, this wouldn't be cheaper. As for stained wood, this is potentially cheaper, but depends on the type of finish and style you change to.

Keep in mind, changing colors also requires changing the exposed surfaces of your cabinetry that are in place. Finished ends can be covered with panels. We call this procedure a re-surfacing job. And we do offer it. The price largely depends on exactly what's necessary to transition your current cabinetry to the color you want.

So without knowing what material your cabinets and doors/fronts are made of, the type of finish already on them, what you want to change them to and the quantity of cabinets, doors and fronts... I can't accurately give you a price or even begin to guess.

My suggestion is taking pics of the cabinets you want to change. If you're not sure what the material your cabinets are made from, take off a small door and bring it into our shop. We can check it out first hand and tell you what would need to be done. Also, if you haven't decided what you want to change it to, it would be great to come in and check out the options we have!

Our show room is located at 1009 N. 1100 West off of Sunset. We're near Dixie Lumber and the Texaco Oil Change center, and close to Papa Murphy's. Feel free to stop in.

Whatever you decide to do, we wish you the best of luck and I want to say this again... Upgrades to cabinetry improve the value of your home! You're making an excellent decision by sprucing up your cabinetry!

Monday, March 6, 2017

Monday, October 17, 2016

PRICE RANGE

GOODWIN MILL AND CABINETS has been getting a lot of requests on our Facebook page to indicate a price range for our cabinets. I'd like to address that with this blog post.

Let me start by saying, like most big ticket items, cabinetry can vary in price based on a number of things. Just like when you shop for a car... If you want a luxury model, you will pay a lot more and if you go with a more standard quality cabinet, you'll pay less.

The reason why it's hard for me to specify our pricing is because we offer both. We can do a simple cost effective cabinet and create a kitchen to fit a smaller budget... But at the same time, we can do a luxury kitchen with all sorts of upgrades, bells & whistles.

We currently have a client we work with who has developed townhomes. The units are uniform in design and we essentially repeat the design in each unit. The only difference is in the actual usable space available once the framing is complete. We alter each unit plan to fit the real space. These cabinets are super simple and extremely inexpensive. The same builder also builds custom homes for his clients. In those cases, we can get some super involved plans and kitchens that require a lot of work.

Now in the past, we've discussed quality and how sometimes the cheapest price isn't the best choice. And we also know even though there is an industry standard for cabinetry in Southern Utah, there are also cabinet makers who cut corners and use cheaper materials to build their cabinets and deflate their price. Even though these prices seem like the best deal, you later end up paying even more when you have to replace parts or hardware.

In the end, the best way to determine the price of cabinetry is to specify exactly what you want, i.e., a luxury or economy or somewhere in between... Kitchen and let us bid the plan. With bids in hand you can shop around and see where the different cabinet professionals in our area come out price wise and you can make an informed decision then.

In the meantime, if you want to know our price range... We can do the low-end economy cabinets (I.e., the 1 star) and we can do the high-end expensive luxury cabinets (i.e., the 5 star) and just about everything in between. We've got you covered!

Let me start by saying, like most big ticket items, cabinetry can vary in price based on a number of things. Just like when you shop for a car... If you want a luxury model, you will pay a lot more and if you go with a more standard quality cabinet, you'll pay less.

The reason why it's hard for me to specify our pricing is because we offer both. We can do a simple cost effective cabinet and create a kitchen to fit a smaller budget... But at the same time, we can do a luxury kitchen with all sorts of upgrades, bells & whistles.

We currently have a client we work with who has developed townhomes. The units are uniform in design and we essentially repeat the design in each unit. The only difference is in the actual usable space available once the framing is complete. We alter each unit plan to fit the real space. These cabinets are super simple and extremely inexpensive. The same builder also builds custom homes for his clients. In those cases, we can get some super involved plans and kitchens that require a lot of work.

Now in the past, we've discussed quality and how sometimes the cheapest price isn't the best choice. And we also know even though there is an industry standard for cabinetry in Southern Utah, there are also cabinet makers who cut corners and use cheaper materials to build their cabinets and deflate their price. Even though these prices seem like the best deal, you later end up paying even more when you have to replace parts or hardware.

In the end, the best way to determine the price of cabinetry is to specify exactly what you want, i.e., a luxury or economy or somewhere in between... Kitchen and let us bid the plan. With bids in hand you can shop around and see where the different cabinet professionals in our area come out price wise and you can make an informed decision then.

In the meantime, if you want to know our price range... We can do the low-end economy cabinets (I.e., the 1 star) and we can do the high-end expensive luxury cabinets (i.e., the 5 star) and just about everything in between. We've got you covered!

Wednesday, May 13, 2015

COMING SOON...

One of the things we're most proud of at Goodwin Mill And Cabinet is our ability to stay ahead of trends in cabinet making. There have been some changes in recent months and our clients are wanting a lot of different and new things. One of the biggest areas of change is finish. Right now paint finishes are all the rage. I'll post some pics soon.

One of the builders we worked for recently announced to me he had photos of all the homes we'd done for them and he's going to let me use those pics to update our website! So get ready for a new and exciting look at our site and new galleries.

We'll post more information in the days to come, but don't hesitate to visit our site and check things out before the big overhaul.

http://www.goodwinmillandcabinet.com

One of the builders we worked for recently announced to me he had photos of all the homes we'd done for them and he's going to let me use those pics to update our website! So get ready for a new and exciting look at our site and new galleries.

We'll post more information in the days to come, but don't hesitate to visit our site and check things out before the big overhaul.

http://www.goodwinmillandcabinet.com

Thursday, January 29, 2015

MODERN WOODWORKING????

I recently heard a comment made in our shop about a piece of custom furniture we were building for a client. The gist of the comment was simply that most of what we build seems out of date. This is a highly subjective opinion, one I wouldn't normally consider responding too except I've heard it from other people as well.

At Goodwin, we're always trying to find new and innovative ways to do our job while at the same time creating fresh and exciting products. We look forward to challenging jobs from smart clients who want to push boundaries and make something interesting. And quite frankly, we pride ourselves on our innovation and ability to stay at the forefront of our industry.

But it's also true we build a lot of custom furniture and cabinets that aren't considered modern or innovative.

Cabinetry and woodworking in general tends to have an old-fashioned look; but with so many alternate materials one can use to build, wood often seems like an unnecessary expensive option. The more inexpensive boxes you can buy at places like Home Depot or even Target are made from plastics or wood substitute materials. Many don't even bother to use a wood facade. The status of a true woodworking has been somewhat replaced by these alternative types of furniture and cabinetry. These are mostly known as composite materials.

To understand the differences between composite materials you need to know the differences between hardwood and softwood. Hardwood comes from deciduous trees, (or trees whose leaves fall off in Autumn) and softwood (which comes from evergreens). Both hardwood and softwood plywoods are often used as the core material for cabinets. The hardwood is generally considered the higher quality of the two. The softwoods do sometimes feature an overlay that strengthens it and will make it suitable for cabinet construction, although it is more often used for smaller things like furniture. You'll see it a lot in big box stores selling coffee tables, entertainment centers or desks you assemble yourself.

Composite metal and plastics are also competing for your money. Often cheaper than wood, easier to paint and more simple to fabricate exact shapes, these mediums are becoming more and more popular with the small end furniture market. Certain Chinese manufacturers are even using similar substances to resin and silicone to create pieces. These items are then painted or distressed to resemble materials like metal or wood. Even so, the biggest threat to wood is the wood composite.

There are different grades of hardwood and softwood composites out there. MDF and Particleboard being two of them. These pressed woods are quite popular with the current trend of paint-grade cabinetry or they can have a colored veneer on the side giving it a finished look before it's even shaped or assembled. They allow for a smoother look and can be just as sturdy and durable as regular wood. They are also less likely to warp.

Right now, one of the biggest trends in cabinetry is in the finish. Many of our buyers are choosing paint finishes over natural wood stain or glazing. They are also opting for cleaner, more simple lines. Flat panel doors are making a huge comeback. The benefit to choosing cabinets of this nature is color. There are more color options in paint grade than there are with stain. Designers can successfully create a fluid color scheme throughout a house by using paint grade to generate highly specific colors.

However, there is a certain status that comes along with wood. It's a staple of the antique furniture community and there's definitely a prestige that is associated with having solid wood pieces. Because of that, solid wood pieces continue to fascinate our clients.

It all comes down to the simple fact that we do what our clients want. If they want a wood dining table, rest assured, we're going to build it. If they want oak, walnut, alder, cherry or any other wood species cabinetry, we're going to do it. After all, our focus is helping our clients achieve their visions when we build products for them. If that vision is modern and progressive, than we're gonna do it. If that vision is more reflective and old fashioned, we're gonna do that.

Ultimately, I think what defines something as modern these days is the accents. A good designer can take some antique with the right lighting and accents, it can look new and vital.

We want to be the tools our clients use to make their dreams come to life. Of course we want you to call Goodwin today and find out exactly how we can help you!

At Goodwin, we're always trying to find new and innovative ways to do our job while at the same time creating fresh and exciting products. We look forward to challenging jobs from smart clients who want to push boundaries and make something interesting. And quite frankly, we pride ourselves on our innovation and ability to stay at the forefront of our industry.

But it's also true we build a lot of custom furniture and cabinets that aren't considered modern or innovative.

Cabinetry and woodworking in general tends to have an old-fashioned look; but with so many alternate materials one can use to build, wood often seems like an unnecessary expensive option. The more inexpensive boxes you can buy at places like Home Depot or even Target are made from plastics or wood substitute materials. Many don't even bother to use a wood facade. The status of a true woodworking has been somewhat replaced by these alternative types of furniture and cabinetry. These are mostly known as composite materials.

To understand the differences between composite materials you need to know the differences between hardwood and softwood. Hardwood comes from deciduous trees, (or trees whose leaves fall off in Autumn) and softwood (which comes from evergreens). Both hardwood and softwood plywoods are often used as the core material for cabinets. The hardwood is generally considered the higher quality of the two. The softwoods do sometimes feature an overlay that strengthens it and will make it suitable for cabinet construction, although it is more often used for smaller things like furniture. You'll see it a lot in big box stores selling coffee tables, entertainment centers or desks you assemble yourself.

Composite metal and plastics are also competing for your money. Often cheaper than wood, easier to paint and more simple to fabricate exact shapes, these mediums are becoming more and more popular with the small end furniture market. Certain Chinese manufacturers are even using similar substances to resin and silicone to create pieces. These items are then painted or distressed to resemble materials like metal or wood. Even so, the biggest threat to wood is the wood composite.

There are different grades of hardwood and softwood composites out there. MDF and Particleboard being two of them. These pressed woods are quite popular with the current trend of paint-grade cabinetry or they can have a colored veneer on the side giving it a finished look before it's even shaped or assembled. They allow for a smoother look and can be just as sturdy and durable as regular wood. They are also less likely to warp.

Right now, one of the biggest trends in cabinetry is in the finish. Many of our buyers are choosing paint finishes over natural wood stain or glazing. They are also opting for cleaner, more simple lines. Flat panel doors are making a huge comeback. The benefit to choosing cabinets of this nature is color. There are more color options in paint grade than there are with stain. Designers can successfully create a fluid color scheme throughout a house by using paint grade to generate highly specific colors.

However, there is a certain status that comes along with wood. It's a staple of the antique furniture community and there's definitely a prestige that is associated with having solid wood pieces. Because of that, solid wood pieces continue to fascinate our clients.

It all comes down to the simple fact that we do what our clients want. If they want a wood dining table, rest assured, we're going to build it. If they want oak, walnut, alder, cherry or any other wood species cabinetry, we're going to do it. After all, our focus is helping our clients achieve their visions when we build products for them. If that vision is modern and progressive, than we're gonna do it. If that vision is more reflective and old fashioned, we're gonna do that.

Ultimately, I think what defines something as modern these days is the accents. A good designer can take some antique with the right lighting and accents, it can look new and vital.

We want to be the tools our clients use to make their dreams come to life. Of course we want you to call Goodwin today and find out exactly how we can help you!

Monday, January 26, 2015

THE QUALITY STANDARD OF SOUTHERN UTAH...

Do a Google search for cabinet makers in Southern Utah and you'll get a dozen or so hits. Websites to visit. And one of the first things you'll read in every single introduction is a commitment to the highest quality. Now that can be confusing and disappointing all at the same time.

Obviously, not every cabinet maker is going to use the same materials. And not every one will treat your job the same as the other guy. So how can they claim to offer or provide the highest quality when comparatively speaking, their work doesn't measure up?

I've been thinking a lot about that recently and there are a number of factors you have to take into consideration as you compare companies in this industry.

The first is the Standard Quality of the area. (And this is a big one).

This may or may not come as a surprise to you, but Southern Utah is a unique place. If you've shopped for a home in Nevada or even Northern Utah you know how different the industry can be.

The language used by the salesman and the language used in a pamphlet may liven you up and make you think you're getting an amazing deal... But it's a lot like holding silver in one hand and stainless steel in the other. You can tell the difference in quality when you can compare them.

Many of these big chain builders use a cheaper cabinet they can either mass produce or order in. When they get the finalized space, they design a cabinet layout using the sizes and shapes available to them. They design your space to fit their cabinets.

The Quality Standard in Southern Utah is abnormally much higher. Although there are cabinet makers who offer lower end quality to their customers for whom price is the most important factor, but thanks to the huge amount of custom building and the Parade of Homes... The standard is a custom design. Which means, the cabinet makers take your space and design custom cabinetry to fit it. It also means the buyer has a lot of latitude in the cabinets that actually go in the home. And a huge amount of say in the look and style of the cabinetry.

By itself, a commitment to quality in Southern Utah, is a commitment to maintain the area standard.

Granted, there are cabinet makers who maintain a commitment to high quality and then don't deliver the goods. Those kinda guys crop up, hang around for a couple years undercutting everyone else in price... But eventually, because their work is below standard, they build a bad reputation and eventually fall by the wayside. That's something you need to watch out for.

And then there is a personal standard that comes into play. Each cabinet maker develops a style, if you will... We've talked in the past about ways cabinet makers will make certain adjustments to cabinet layouts in order to lower their bids. Tricks like eliminating Drawer Banks, or taking a larger cabinet and reducing two doors to one. These tricks may help make one bid seem better than another, but it also speaks to the character of the cabinet maker himself.

Even though a cabinet maker may use all the right materials, build a custom cabinet and follow the design specifications given to him by the customer, there are still ways he can compromise his product. He could use inferior hardware or take shortcuts in production to save time and money. The drawer boxes could be built from inferior quality material compared to the box. But it won't be noticed in the context of the drawer front and the box itself.

Making a decision... Choosing a cabinet maker is no simple task. Especially if you're planning on building your own home as an owner/builder.

So what else do you look for when you consider a cabinet maker?

One of the best ways to find a cabinet maker you feel confident with is to check out their work. Ask to visit current jobs and spend some time walking through a newly installed kitchen or bathroom. Open doors and drawers. Pay attention to the layout and see how functional it feels to you. Observe the detail of the design. Is it vital? Fresh? New? Exciting?

Another way to choose a cabinet shop is their willingness to work with unusual mediums. Maybe you suggest a less popular, more difficult wood like Oak. A company who isn't afraid of a challenge will take up a challenge of a different wood species.

Bring some interesting ideas to the table. Think of something unusual and ask the designer if it's possible to build that piece. An innovative company will consider the possibility of doing something interesting and new.

Even though major design magazines might suggest trends in cabinet making and design, we've found over the years design trends in Southern Utah seem to have a life of their own. Visiting home shows and checking out open houses of new models will give you some idea what's happening locally. That doesn't mean you should ignore national trends. Especially if you like them. But it's a good indicator if a company is staying current with local design trends.

The true test of a cabinet maker in Southern Utah is innovation, style and the ability to incorporate a client's vision to create a truly unique custom cabinetry set.

The quality is something you can expect. So look for the more interesting aspects of a company to determine their ability to do your job.

Of course, Goodwin Mill And Cabinet, LLC is exactly the kind of company you're looking for. On this matter, I'm certain. But don't take my word for it, put us to the test and see how we measure up.

There's no harm in setting up an appointment today. And no harm in getting a bid on your job. Make sure you get the latest in style, innovation and technology. That's just what you get when you choose Goodwin as your cabinet maker!

Obviously, not every cabinet maker is going to use the same materials. And not every one will treat your job the same as the other guy. So how can they claim to offer or provide the highest quality when comparatively speaking, their work doesn't measure up?

I've been thinking a lot about that recently and there are a number of factors you have to take into consideration as you compare companies in this industry.

The first is the Standard Quality of the area. (And this is a big one).

This may or may not come as a surprise to you, but Southern Utah is a unique place. If you've shopped for a home in Nevada or even Northern Utah you know how different the industry can be.

The language used by the salesman and the language used in a pamphlet may liven you up and make you think you're getting an amazing deal... But it's a lot like holding silver in one hand and stainless steel in the other. You can tell the difference in quality when you can compare them.

Many of these big chain builders use a cheaper cabinet they can either mass produce or order in. When they get the finalized space, they design a cabinet layout using the sizes and shapes available to them. They design your space to fit their cabinets.

The Quality Standard in Southern Utah is abnormally much higher. Although there are cabinet makers who offer lower end quality to their customers for whom price is the most important factor, but thanks to the huge amount of custom building and the Parade of Homes... The standard is a custom design. Which means, the cabinet makers take your space and design custom cabinetry to fit it. It also means the buyer has a lot of latitude in the cabinets that actually go in the home. And a huge amount of say in the look and style of the cabinetry.

By itself, a commitment to quality in Southern Utah, is a commitment to maintain the area standard.

Granted, there are cabinet makers who maintain a commitment to high quality and then don't deliver the goods. Those kinda guys crop up, hang around for a couple years undercutting everyone else in price... But eventually, because their work is below standard, they build a bad reputation and eventually fall by the wayside. That's something you need to watch out for.

And then there is a personal standard that comes into play. Each cabinet maker develops a style, if you will... We've talked in the past about ways cabinet makers will make certain adjustments to cabinet layouts in order to lower their bids. Tricks like eliminating Drawer Banks, or taking a larger cabinet and reducing two doors to one. These tricks may help make one bid seem better than another, but it also speaks to the character of the cabinet maker himself.

Even though a cabinet maker may use all the right materials, build a custom cabinet and follow the design specifications given to him by the customer, there are still ways he can compromise his product. He could use inferior hardware or take shortcuts in production to save time and money. The drawer boxes could be built from inferior quality material compared to the box. But it won't be noticed in the context of the drawer front and the box itself.

Making a decision... Choosing a cabinet maker is no simple task. Especially if you're planning on building your own home as an owner/builder.

So what else do you look for when you consider a cabinet maker?

One of the best ways to find a cabinet maker you feel confident with is to check out their work. Ask to visit current jobs and spend some time walking through a newly installed kitchen or bathroom. Open doors and drawers. Pay attention to the layout and see how functional it feels to you. Observe the detail of the design. Is it vital? Fresh? New? Exciting?

Another way to choose a cabinet shop is their willingness to work with unusual mediums. Maybe you suggest a less popular, more difficult wood like Oak. A company who isn't afraid of a challenge will take up a challenge of a different wood species.

Bring some interesting ideas to the table. Think of something unusual and ask the designer if it's possible to build that piece. An innovative company will consider the possibility of doing something interesting and new.

Even though major design magazines might suggest trends in cabinet making and design, we've found over the years design trends in Southern Utah seem to have a life of their own. Visiting home shows and checking out open houses of new models will give you some idea what's happening locally. That doesn't mean you should ignore national trends. Especially if you like them. But it's a good indicator if a company is staying current with local design trends.

The true test of a cabinet maker in Southern Utah is innovation, style and the ability to incorporate a client's vision to create a truly unique custom cabinetry set.

The quality is something you can expect. So look for the more interesting aspects of a company to determine their ability to do your job.

Of course, Goodwin Mill And Cabinet, LLC is exactly the kind of company you're looking for. On this matter, I'm certain. But don't take my word for it, put us to the test and see how we measure up.

There's no harm in setting up an appointment today. And no harm in getting a bid on your job. Make sure you get the latest in style, innovation and technology. That's just what you get when you choose Goodwin as your cabinet maker!

Monday, December 8, 2014

THIS IS HOW YOU DESIGN A KITCHEN....

Goodwin Mill and Cabinet here and today we're taking you on an in depth look at the steps a cabinet designer goes through to create cabinets in your new home. So sit down for a bit, browse the pics below and read all about how cabinets are designed!

The very first thing you need is a blueprint. A plan. This particular plan was loaded will all kinds of instructions, but we've edited out all of them and left only information that is important to the design behind. The plans give us a lot of information we need when we start designing. It tells us where the appliances need to go and what kinds of appliances are going to be in that kitchen. For example, this kitchen calls for a sub-zero refrigerator. The standard size for home refrigerators is 36". This one is calling for a 48" space so we know it's a sub-zero. We also know roughly where other things like plugs and pipes are going to go because of where the architect puts the sinks, etc. etc.

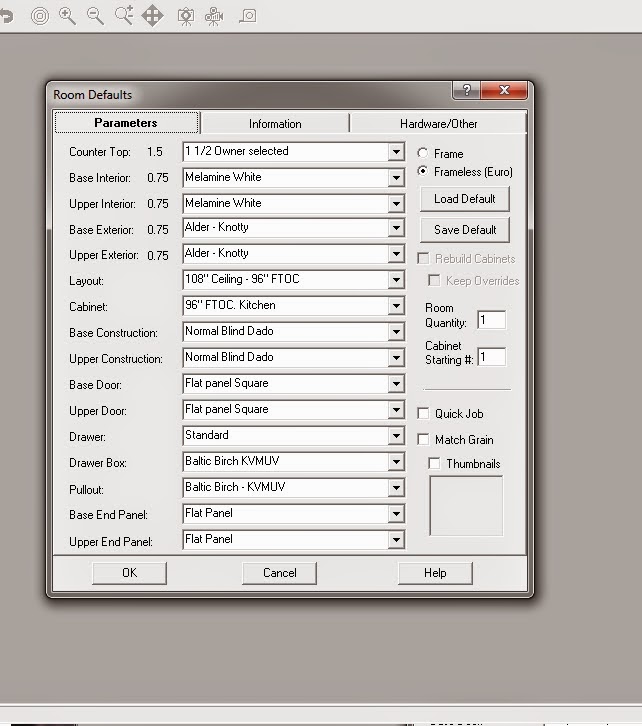

We're ready to begin. So after opening our cabinet design software, we immediately open a new room for editing and specify all of the parameters we can. For example, the owners of this home have chosen to use knotty alder wood for their cabinets. You can see some of the other details as well. At this point, we want to get as much information entered as possible. If the buyer has picked out a stain and finish color, we can enter that here. If they've picked handles and knobs we can add those as well.

Next, we need to identify which walls we're going to reproduce and do a rough outline of the work space. we know which walls we need to reproduce based on which walls are supporting cabinets. In this kitchen there are three with an additional island wall we will have to build. I've used red arrows to point to the walls we need to duplicate in our design and I've set up three walls that roughly resemble the walls we need.

Now that we've made the rough figure, it's time to get technical. Using a ruler and the blueprint scale, we determine the exact length of each wall and we edit our drawing to reflect it. This is also the time we add anything in the wall that could conflict with cabinets; such as windows, doors, etc. etc. Of these three walls, only one has a doorway. We've identified it on the plan and added it to our drawing. Right now, our drawing reflects the architects exact design of the space. Keep in mind, once the home is built, we may have to adjust some of our figures. Framed walls don't always end up exactly the same length as they do on the plan. We need to be able to adjust for real space before we start building the cabinets.

There is a fourth wall in this kitchen and using the dimensions specified on the plan, we can plot out where that wall will go. In this next picture, you can see the island wall is added. Once again, using a ruler and the scale from the blueprint, we took one point on the island and measured the distance from it to the two closest walls. In the case of this house, the south and west walls. Where those two points connected is where the starting point of our island will be set. So now we have every surface we plan to build on represented in the drawing.

The next step involves a lot of the same activity we've done so far. The next step is adding the appliances. Since appliances; like windows and doorways, can conflict with a cabinet design, we need to map them out before we go any further. This kitchen has four appliance spaces. A dishwasher, a sub-zero fridge, a cook top and a cabinet designed to stack double ovens with an additional microwave. We add the appliances and now we can see where the cabinets will go and what they will be next to.

And now the fun really begins! At this point, we need to fill the space allotted for cabinetry. We run basic base cabinets along the walls and then do the same with the uppers. Now our kitchen is loaded up. We have a visual representation of the space and how we will fill it. It's important to understand two things at this point... 1) This drawing generates a cut list for each cabinet. Therefore, the drawing helps us tell how much each cabinet will cost in materials. It will generate a figure for a bid. 2) We will re-design it at least three more times before we have our kitchen. The first time is now. We will pull up each elevation and adjust it to make it more functional. The second time is when we meet with the client. They will go over the design and we will change it to reflect their desires. Perhaps they want less or more drawers, or maybe they want to add a mini-fridge. Whatever they choose, we will change it to reflect their wishes. The last time is when we get a field measurement of the space. We will adjust our drawing to reflect the true numbers. This step won't require redesigning, but it can drastically alter your cabinets sizes and cutting list.

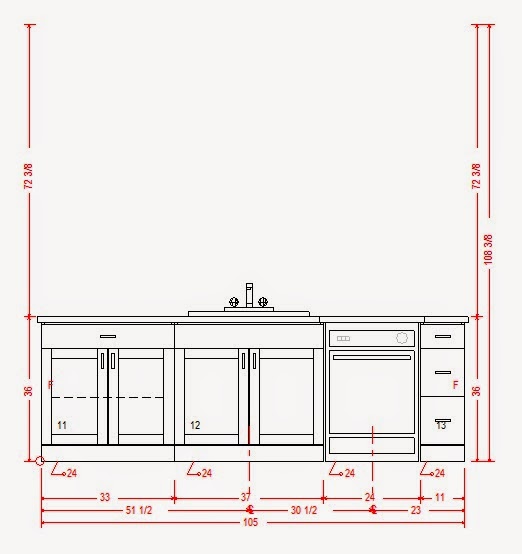

This is an example of quick basic design. This wall is the island wall. The dishwasher prevents us from having a meaningful cabinet on the end. These other two can be similar, but the cabinet in the middle is a sink cabinet and calling for a 36" sink. Therefore, the middle cabinet needs to be the biggest. One basic rule of design is to create a functional space. We try and include at least one drawer bank in a kitchen. The middle cabinet will be a sink cabinet and the final cabinet can be pretty much whatever we want. For now, we'll leave it as a standard drawer/door cabinet.

This pic shows the same wall after we've done some simple design work. We took the small cabinet farthest right and turned it into a drawer bank. We made the middle cabinet the largest on the wall, drew in a 36" sink to make sure it would fit and left that cabinet a simple door/drawer combo. We jazzed up the design, made it more functional, kept the appliance where it needed to be according to the blue prints and overall, improved its appearance. All of that with just a few simple changes. But we're not done with the island just yet. The back of the island needs to be covered with a base wainscoting of knotty alder. Also, according to the plan, that wall needs to be 42" in height. This means the owner wants a bar on that side and the counter top will extend out over the island.

So in this pic, we added the wainscoting, raised the wall and extended the bar. We also gave it that arch, just like it appears on the plans. Usually, you'd save any counter top work until the entire kitchen was done, but since we were already working on the island, I decided to just finish it up.

The final task is completing a simple design on each surface. We won't add a bunch of expensive cabinets like garbage pullouts, spice racks, lazy susans, breadboards or utility closets. All base cabinets will be the simple door/drawer combo. We will try to use as few as possible because each additional cabinet increases our bid and right now, we're just preparing for the bid. High end, more expensive cabinets will be discussed when the client has the chance to go over the plans. So we've kept it light, as inexpensive as possible and we've followed the plan as exactly as we were able. Are you ready to see the final result?

This is a 3D representation of the kitchen we just designed. Notice the wainscoting under the raised bar. If you look closely, you won't find a great deal of variation in the cabinetry. But this is the starting point we needed to prepare for the client. Now, we can submit a bid, meet the client to make changes and begin to order hardware.

This is a 3D representation of the kitchen we just designed. Notice the wainscoting under the raised bar. If you look closely, you won't find a great deal of variation in the cabinetry. But this is the starting point we needed to prepare for the client. Now, we can submit a bid, meet the client to make changes and begin to order hardware.Just for fun, I wanted to show the front of the island so you could see the dishwasher, the drawer bank and the sink. These 3D renderings are wonderful because you can program them to do all kinds of things. It can reproduce different stain colors and finishes. It can also show detail like raised panels on doors. There is an element of animation in the rendering, but if you can suspend disbelief, you can very easily see what your kitchen will actually look like when it's installed.

There is one final think I'd like to mention about the 3D rendering and that is how much you can learn from it. Take this pic for example. Sometimes, when you're putting cabinets together, they don't seem to fit. You can see how that might be a problem here. The cabinet over the fridge and the double oven cabinet 25.5" deep while the regular upper cabinets are much more shallow. If I'd not been able to make the cabinets line up and fit nicely together, the crown molding would have returned back to the wall. Instead, it cuts back and then cuts left again when the next cabinet starts. Very clean molding lines means a clean fit for the cabinets in that elevation.

Wow!!! That's basically all there is to it. Some plans can be more difficult than others to design. That usually depends on the architect who designs the space. We've had some plans with angles and patterns... Lots of crazy twists and turns. It does happen, but fortunately, those kinds of plans are few and far between. We do look forward to them though. There's nothing more satisfying than designing a cabinet layout for a tricky space. Especially one the builder/owner likes.

Call Goodwin Mill And Cabinet for your next cabinetry project and let us show you just how amazing cabinetry can be. Happy Holidays from all of us!

Tuesday, October 21, 2014

THE STORY OF THE TEARDROP TRAILER - PT. 19

Installation of the gas lifts was the next step in the project. Chris did it over the weekend and it fit perfectly on the first try. The lifts were purchased from a company that had gone out of business and was in the process of liquidating inventory. They worked great. He lifted the lid about 12" and the lid slowly opens the rest of the way. It is easy to put down without any effort at all. They work better than then the boys ever imagined they would.

As you can tell, they had to replace the leather straps on the trunk. The black genuine leather belt straps broke after the first weekend. They discovered small print on the belt saying the genuine leather had some man made fibers. What is really had was a microscopic leather veneer with cardboard interior. They avoided buying imitation straps the second time. They also installed some sash locks to pull the lid down tight and keep it secure.

This is a side view showing how the trailer looks with the trunk complete and closed. It looks super dusty. But that's par for the course when it's sitting in the shop.

The boys installed a lid stay so they could access the box without holding the lid up by hand. They also put in the battery tie downs so the battery doesn't bounce all over the place. This pic seems a little strange in it's color because the flash is bouncing.

This is the side view of the completed trailer. Magnifico! It looks amazing!

This pic shows the fold down stabilizers. There are four, one for each corner. They will make it nice when the wind blows so you're not rocking all over the place.

This picture shows the undercarriage after it was all sealed with rubberized coating. They used this coating so it would be easy to re-coat when necessary.

There are still a few minor things left to complete at this stage and they are:

01. Complete the plumbing hook up to the pump.

02. Add a light in the trunk lid.

03. Insulate the ice chest in the front trunk.

04. Complete the oven insulation and slide out.

05. Clean the over-spray off the roof vent.

06. Putty, seal and weatherstrip the door frames.

And that will wrap it up. Chris commented at this point that all they needed was one free morning and everything would be finished.

For those of you who have read the story, maybe you've been lucky and seen the trailer in Utah or surrounding states. The boys have taken it all over the place. They've stopped and given a lot of people a closer view. They wanted to post a blog about trips they've taken with the trailer.

My next entry will show pics from one of these trips. You'll be able to see the trailer in action! Goodwin Mill And Cabinet is where you'll find other amazing craftsman pieces similar to the teardrop trailer. You can see more galleries of our work and check out more information about the guys who built the teardrop trailer by visiting:

Subscribe to:

Posts (Atom)